Non-destructive/contact Materials Research and Testing

The right materials in the right place are essential for the quality, service life, weight and ultimately the success of the end product. Optomet laser Doppler vibrometers make important contributions on a global scale to the systematic search for new findings in material research. This applies both to the determination of material parameters or to non-destructive testing/non-destructive inspection (NDT/NDI). Non-contact measurement methods are critical in NDT/NDI as the vibrometer measurements do not change the material characteristics.

Non-destructive testing of materials (NDT)

Carbon fiber reinforced polymer (CFRP) is becoming increasingly important in component production in order to reduce weight and achieve high specific stiffness. Examples are the manufacturing of aircraft wings in aviation or body parts in the automotive industry. Delamination or cracks must be localized quickly during production or maintenance checks to avoid premature material fatigue. With high-frequency excitation of thin-walled CFRP panels, for example by piezo elements, Lamb waves (short-wave surface waves) are generated. These interact with defects in the material, which leads to variations in the wave propagation or to local resonances (Local Defect Resonance – LDR).

Optomet Scanning Laser Doppler vibrometers can detect the in-phase propagation of the waves at every measurement point on the material surface and thus visualize non-destructive defects in the material that are not visible to the naked eye. The internal signal generator can generate any waveform that can be used to excite the components, such as pulses or frequency sweeps. The OptoSCAN software is used to carry out the entire measurement from the setting of the measurement channels to the determination of the measurement points to the visualization and analysis of the measurement data in the frequency and time domain. Using the export function, the data can be exported in standard formats such as UFF, HDF5 and mat-files (MATLAB) and thus further processed.

Examples:

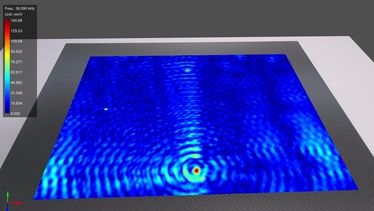

By using the Optomet Scanning Vibrometer, defects introduced on the back of a CFRP plate are detected. The internal signal generator generates a rectangular pulse to excite a piezo actuator, which is attached to the CFRP plate. The waves propagating from the piezo element (bottom center) interact with the two defects, making them visible in the time and frequency domain through locally higher amplitudes (local defect resonance – LDR).

Split Hopkinson Bar (SHPB)

A Split Hopkinson Bar test is a method for material testing, where material properties are determined under dynamic conditions. In this process, the object under test (e.g. a concrete cylinder or a composite) is located between two bars, the incident bar and the transmission bar. An accelerated striker impacts the incident bar where it causes a shock pulse. The generated wave passes through the first bar and hits the material sample and propagates through it into the transmission bar.

Due to their high sampling rate of 160 Msamples/s and a dynamic range of more than 220 dB, laser Doppler vibrometers (LDV) from Optomet are the perfect measuring tool in order to measure the temporal progression of these highly dynamic shock pulses.